- Contact

-

- North America

- EMEA

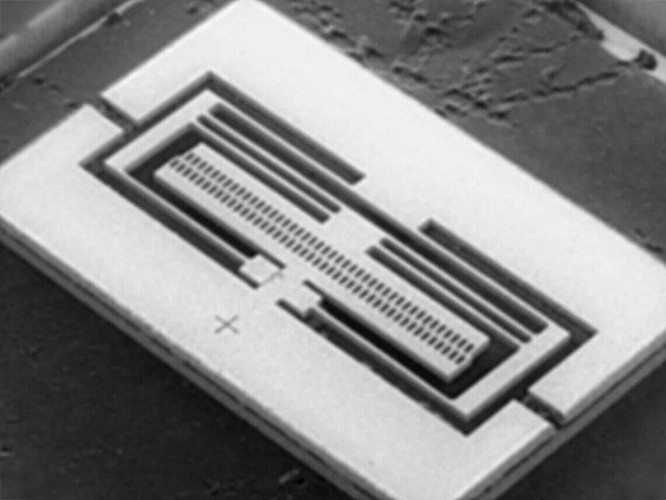

Atomic Machines is reinventing fabrication through a new approach to manufacturing. As a stealth-mode startup, the company is developing advanced machines with an initial focus on microelectromechanical systems (MEMS), overcoming the limitations of traditional silicon-based fabrication. This work lays the foundation for a transformative shift in how complex systems are built at the microscale.

Arena PLM and Onshape CAD

Frictionless cloud-native connection with Onshape

Significant gains from faster approvals and bottleneck resolutions

|

|

Arena PLM and Onshape CAD

Frictionless cloud-native connection with Onshape

Significant gains from faster approvals and bottleneck resolutions

With deep roots in aerospace and defense, medical industries, and energy and power, Atomic Machines encountered a familiar problem with a twist. Despite the company’s investment in advanced product design and development software solutions, there was little structure around how they were being used. Computer-aided design (CAD) and product lifecycle management (PLM) administration were split between engineers and buyers, both lacking the process experience necessary to fully integrate and optimize the systems.

Without someone managing these systems, their true potential remained untapped. The company’s engineers faced challenges with version control, manual processes for engineering change orders (ECOs), and inconsistent documentation. Workarounds were being used to accommodate the lack of automated workflows, as well as critical engineering processes like weldmount handling.

—Michael Hill, CAD/PLM Administrator, Atomic Machines

Upon joining Atomic Machines, Michael Hill, an experienced CAD and PLM specialist, took on the task of developing and standardizing processes across Onshape CAD and Arena PLM. This marked a turning point in the company’s approach to more efficient product development.

With previous experience using a variety of PLM systems, he was already familiar with Arena and knew its robust capabilities. Onshape provided a refreshing CAD solution where engineers were no longer tethered to CAD towers or local servers for their designs. Onshape provides fast, powerful modeling tools to use anywhere and fosters collaboration, even on basic laptops.

The real surprise came from experiencing Onshape and Arena as fully connected, cloud-native solutions. Michael quickly realized the benefits of working within a closed-loop ecosystem. He said, “Because Onshape and Arena are PTC products, support is all under one roof. If there’s an issue, support from either side can talk directly. That alone is gold.”

Instead of patching together CAD, product data management (PDM), and PLM using connectors from different vendors, Atomic Machines now has a seamless, unified platform for release, revision, and change management processes without middleware. Michael leveraged this connection to create common processes and best practices for engineers to follow. Recently, he collaborated with the PTC Connection team to optimize a cross-functional process. The result is an even better solution than the one he had envisioned, one that is now part of the released product.

Michael built the foundation for Atomic Machine’s scalable change management approval process by developing an engineering change request (ECR) process to work like a formal change control board (CCB). Engineering managers, stakeholders, and subject matter experts (SME) use the board to cover a wide range of issues such as: initiate discussions, assess the feasibility and necessity of the change, document the proposed changes before any implementation, as well as evaluate, review, approve or reject designs, processes or specs. “With Arena, I can build the system I need. Every PLM has its limitations, but Arena’s flexibility has let me shape it to our exact needs,” he noted.

In just six months, Atomic Machines saw a complete transformation in how engineering and operations teams collaborated. Documentation that was once nonexistent now lives in Arena, linked to parts, assemblies, and change records. The team replaced tribal knowledge and Slack messages with repeatable, transparent processes.

One of the biggest wins was the reduction in manual rework and miscommunication. Atomic Machines used Arena Tickets for closed-loop issue management to create a comprehensive purchase order tracking system. Purchase orders now include engineering change orders (ECOs), change details, and quotes to improve the tracking and management of orders.

In addition, Onshape’s cloud-native CAD environment constantly saves designs so Atomic Machines can revert to previous versions and experiment with different design branches. This approach facilitates collaboration among engineers, enabling them to merge changes seamlessly and maintain a clear history of design iterations. Coupled with the connection to Arena, Atomic Machines has a fully synchronized change management process that provides visibility for the entire product team.

The company resolves issues before production runs using Arena’s automated workflows like design confirmation and real-time collaboration. Michael said, “With the Onshape-Arena Connection, everything runs smoother now. Buying is better, timelines are clearer, and the system gives us confidence in what we’re building.”

Unlike past experiences with other vendors, Arena and Onshape support teams are proactive, transparent, and responsive. Michael noted that when issues arise, they’re addressed quickly, often within 24 hours. “The support has made me biased. I tell people here, ‘Submit a ticket. If you don’t have the answer today, you’ll have it tomorrow.’ And I’ve been right every time.”

Looking forward, Atomic Machines plans to expand fully into using Arena’s quality and supplier management modules as they grow. They’ve already begun using Arena’s training module to manage safety and onboarding. The long-term plan includes building out prototype, pilot, and production release workflows with automation layered in once processes are refined.

Arena and Onshape are foundational to the company’s future. “We’re building the system we’ll need when we scale. And if Arena doesn’t have it today, I’m confident they will by the time we need it,” said Michael. The Onshape-Arena Connection has allowed Atomic Machines to avoid the common startup pitfall of relying on spreadsheets and email until chaos forces a change.

The company’s early investment in digital infrastructure like cloud-native PLM and CAD highlights a core tenet of their philosophy—building for scale from day one. By prioritizing control over their intellectual property and aligning their development processes with long-term manufacturing goals, they’ve positioned themselves not just to prototype rapidly but to transition seamlessly into production.

Atomic Machines uses Arena’s cloud-native platform as their backbone for collaboration, compliance, and traceability. They set a new standard for how advanced manufacturing startups operate. In an industry where the race to market can overshadow sustainability and structure, their approach is a compelling blueprint for companies aiming not just to launch but to lead.

—Micheal Hill, CAD/PLM Administrator, Atomic Machines